At 77 metres high, the University of Toronto’s 14-floor Academic Wood Tower (AWT) will be the tallest mass timber building in Canada when its classroom doors open in 2026.

The tower is novel not just because it is a timber hybrid structure, but also because it is being constructed atop the Goldring Centre for High Performance Sports, a busy facility at the University of Toronto’s main campus.

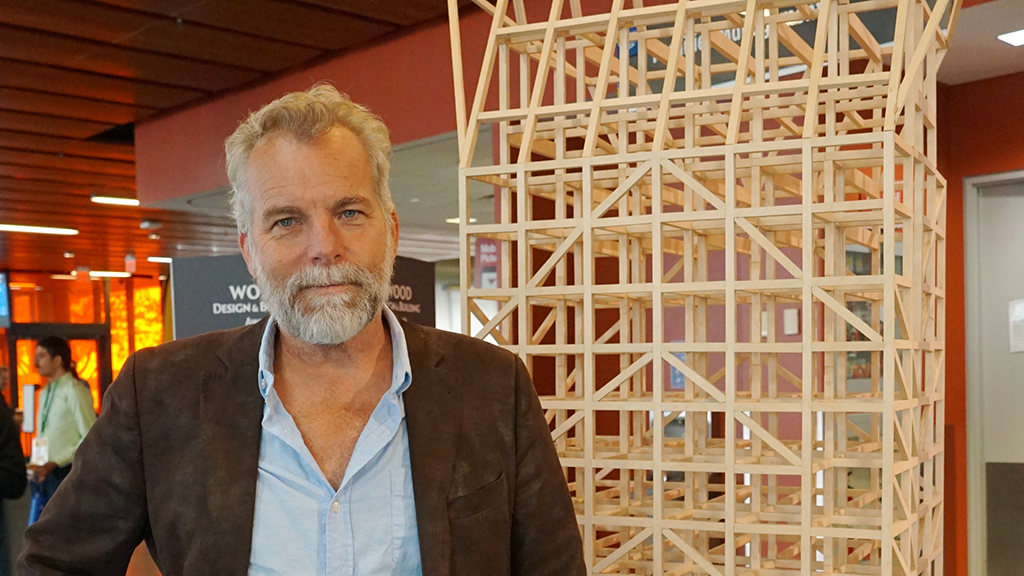

The timber is required “to do a lot of things mass timber really doesn’t like to do,” said Ryan Mitchell of MJMA Architecture and Design, which is in joint venture with Patkau Architects on the project.

One of the issues resolved was how to incorporate the 6.4-metre cantilever because “timber doesn’t want to hang unsupported,” said the project architect who was a panellist at a seminar, A Case Study on the AWT, at the Buildings Show 2024 in Toronto recently.

Another hurdle overcome was with the foundations which were designed for a steel structure, not a heavy mass timber one, when the sports facility was constructed a decade ago below the now rising wood tower, he told a packed room at the Metro Toronto Convention Centre.

Notwithstanding challenges the design and engineering team faced early on, Mitchell said the rationale for choosing mass timber over conventional materials included its sustainability and constructability.

Panellist Ryan Going, a project manager with Pomerleau, the construction manager of the project, told the seminar audience that as finished structural panels are assembled in a factory it “makes our lives a little bit easier” on the confined site with little laydown space available for equipment and materials.

Still, the tight site presented problems that required innovative solutions.

Pomerleau’s construction trailer complex, for one, had to be set atop a “giant scaffold” over the exit stairs from the existing sports facility’s below-grade volleyball court, Going said.

The contractor also had to rip up an area of an existing lobby space for the placement of its free-standing tower crane, credited as the tallest of its kind in North America.

Going said a traditional stick-built design would have faced more logistics and sequencing hurdles.

He added it was important that Pomerleau was retained early in a design-assist role to work on build details.

The contractor included some of its key trades, including curtainwall, mechanical/electrical, mass timber and steel subcontractors.

The tower features a dynamic external brace frame.

Simon Rayment, the project’s lead engineer of Blackwell Structural Engineers, told the seminar the south face of the building is a truss, spanning 32 metres and repeating every three floors. That truss is supported by braced walls on the east and west sides.

Rayment said the team had to address the stress placed on the structure caused by shrinkage of timber at connections to steel, the building material required by the City of Toronto for the stair course.

“Everything moves. Steel expands and contracts in (changing) temperatures and concrete shrinks as well, but that all happens before the finishes are on.”

By comparison, he said the mass timber required “extra special attention to details” because it will take up to three years for the large timber elements to season or dry.

Panellist Kevin Key, associate principal with Smith + Andersen, a mechanical/electrical systems engineering firm, says to maximize energy efficiency the envelope will feature triple pane glazing and a ventilation system decoupled from the heating/cooling network. Chilled beams will be used in offices and classrooms.

Installing a heat recovery chiller through the concrete loading dock into the basement “and wheeling it around down there while the existing systems were operational was no small feat,” Key said.

Mitchell suggested that over-building (building on top of existing buildings) such as the AWT makes sense in inner cities like Toronto where developable land is becoming rare.

“I think that mass timber is a fantastic resource in new and overbuild or retrofit construction.”

The seminar was moderated by Mike Yorke, a consultant to the industry and former president of the Carpenters’ Regional Council (Local 27).

Recent Comments